Product Center

Contact Us

Hotline:020-82210779

E-mail:junjiegood@vip.163.com

5th Floor, Building 2, No. 9 Lanyu Fourth Street, Guangzhou Economic and Technological Development Zone

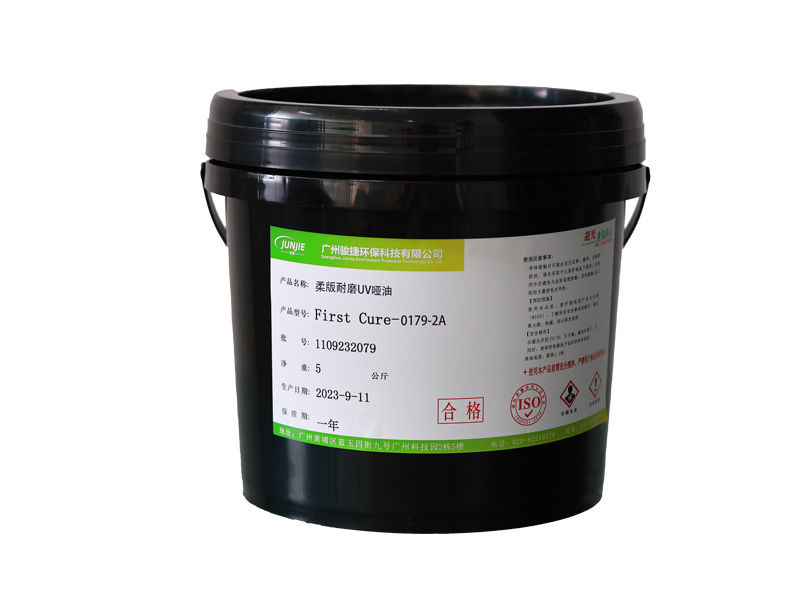

Flexographic ink

Category:

Key:

UV curing Digital ink

Flexographic ink is a special type of ink suitable for flexographic printing technology, mainly composed of pigments and resin binders. It has the characteristics of low viscosity, good fluidity, and easy drying, and is widely used in printing various packaging materials such as plastic film, metal foil, paper, and corrugated paper.

The biggest feature of flexographic ink is that the solvent used does not soften, swell, or deform rubber and photosensitive resin plates, ensuring printing durability. According to the main resin or raw material used in the formula, there are flexible acrylic ink, flexible polyurethane ink, flexible polyamide ink, flexible dye ink, flexible water-based ink, flexible nitrocellulose ink and other types of ink, water washable ink, etc.

The preparation method of flexographic ink is based on dissolving polymers in the ink, and typical solvents used are water and alcohol, as well as small amounts of ethylene glycol ether, ethyl alcohol, and aliphatic hydrocarbons. The material used to manufacture this printing plate has undergone changes, including the use of rubber and photosensitive resin.

The printing technology of flexographic ink has the advantages of good printing quality, wide range of printing materials, fast printing speed, and low cost. At the same time, it is important to choose appropriate printing equipment and ink, control printing parameters and ink layer thickness to ensure the quality and stability of the printing effect.

Widely used in industries such as cosmetics/daily necessities hoses, labels, packaging printing, book and magazine printing, express label printing, electronic label printing, etc., personalized customization can be carried out according to customer needs.

Welcome to your inquiry message

Related Products